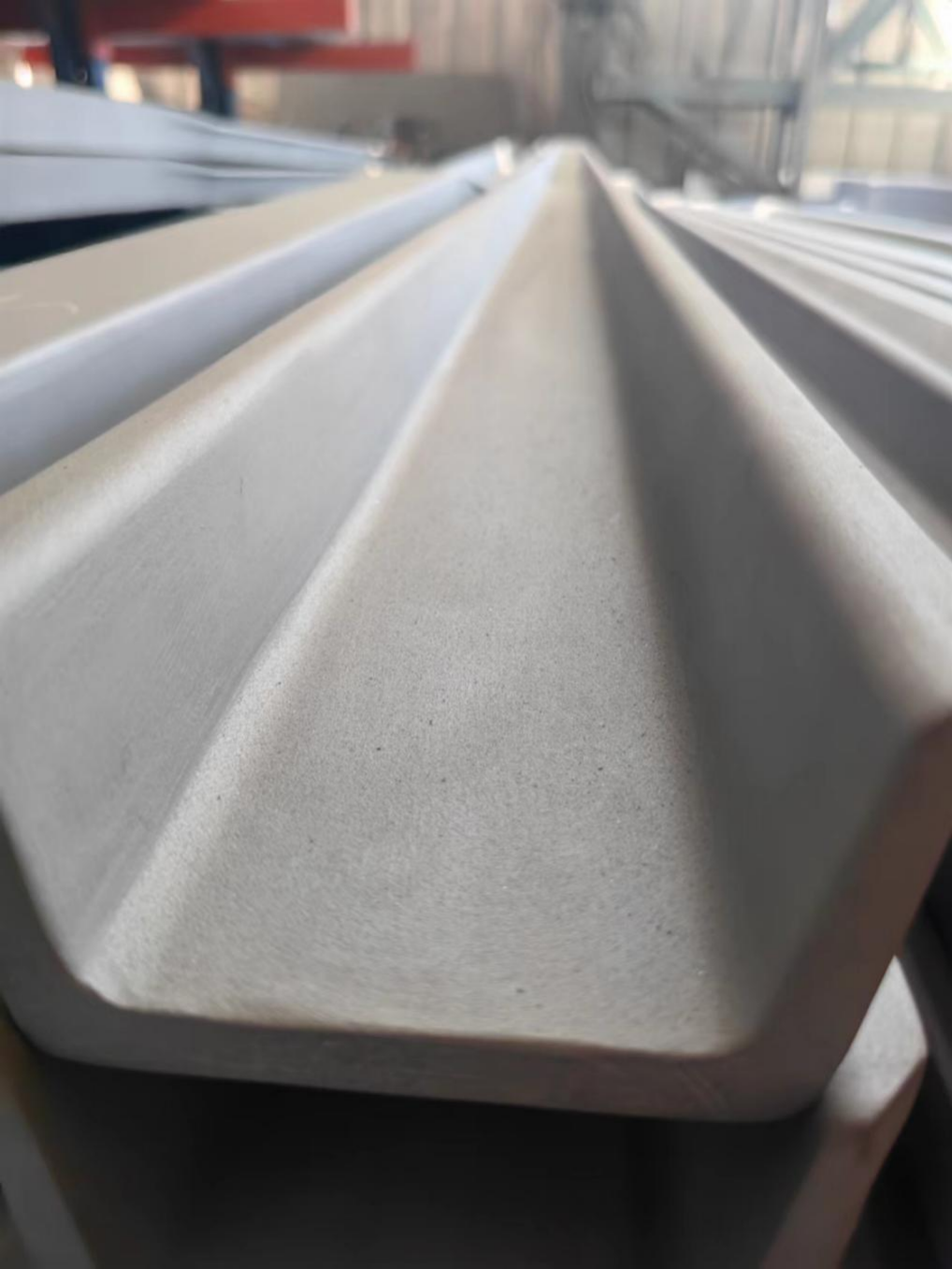

Reaction sintered silicon carbide has high density, delicate crystal structure, and good mechanical properties. High strength and good resistance to thermal shock. Not only does it occupy a stable market share in industrial kilns and other fields, but it also opens up new applications in multiple fields, such as military industry, photovoltaic industry, and semiconductor industry materials. Especially in the photovoltaic field, the production and production of diffusion propellers, boat supports, boats, and structural components have stable quality, high dimensional accuracy, the largest shipment volume, strong production capacity, and joint research and design with customers. Comprehensive pre-sales and after-sales services have a good reputation and influence in the industry.

| Entry name | Index | ||

| Quality assurance (performance indicators) | SiC | % | 90~92 |

| Free silicon | 5 | 8~10 | |

| Bulk density | g/cm3 | >3.01 | |

| Porosity | % | <0.1 | |

| Bending strength (20 ℃) | MPa | 260 | |

| Bending strength (1200 ℃) | MPa | 280 | |

| Compressive strength (20 ℃) | MPa | 900 | |

| Hardness | Kg/mm2 | 2400 | |

| Thermal conductivity (1200 ℃) | w.m-1.k-1 | 45 | |

| Thermal expansion coefficient (1200 ℃) | α×10-6/C | 4.5 | |

| Elastic modulus (20 ℃) | GPa | 330 | |

| Maximum service temperature | ℃ | <1380 | |